Scheduling

Optimization-Based Production Scheduling Decision Support System

AI and Optimization-Based Scheduling

It automatically and dynamically creates production plans using advanced heuristic algorithms and optimization techniques.

Simulation-Assisted Flexible Planning

Users can instantly simulate the impact of results by changing work orders and schedules through the interface.

Manual Intervention and Fast Rescheduling

Make changes easily and quickly provide a re-optimized schedule.

Machine and Operation Management

Detailed production instructions can be defined and tracked with machine groups, operations, and bills of materials.

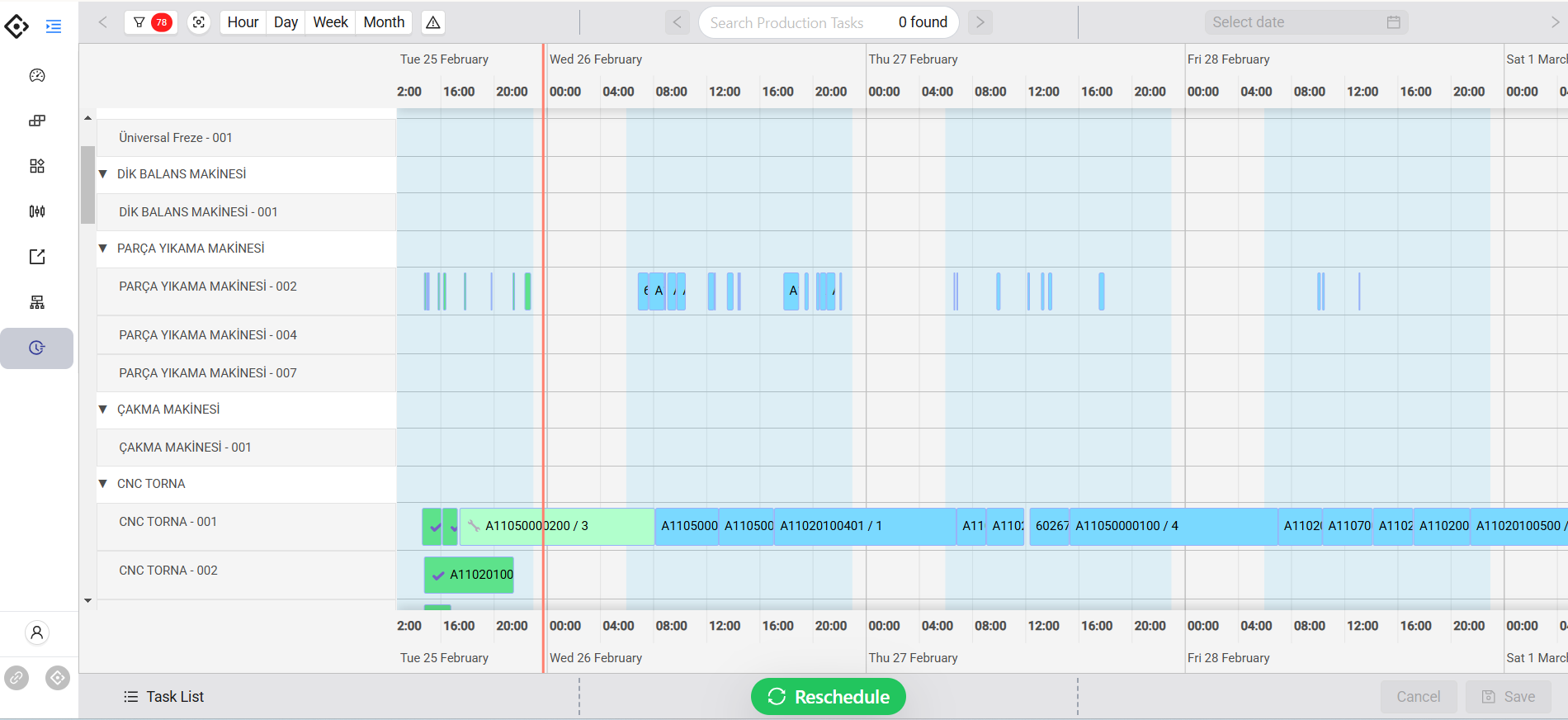

Comprehensive Visualization and Reporting

Clear tracking of operations based on machines and timeframes is provided with a Gantt chart. KPIs are reported in detail.

ERP and IoT Integration

Supports the effective execution of the schedule with real-time data flow.

Optiway SCH is a powerful software solution that elevates the scheduling of work orders in companies' production processes to a higher level with artificial intelligence and optimization algorithms. By integrating data from ERP and IoT devices, it automates the scheduling tasks that production planning engineers often perform manually and with basic algorithms (FIFO, LIFO) in a dynamic, simulation-supported, and user-friendly interface.

Developed for large-scale companies, our software presents to the user which job should be done on which machine and when, based on artificial intelligence and optimization. Based on data from ERP and IoT devices, our software presents the scheduling of work orders, which is currently done with basic algorithms (FIFO, LIFO) and mostly manually by Production Planning Engineers, on an optimization basis. The system optimizes which job should be done on which machine and when, while allowing users to quickly define instant changes and see the results through interactive simulations. Thus, while flexibility in the production flow reaches its peak, the planning process gains efficiency and accuracy.

The system optimizes which job should be done on which machine and when, while allowing users to quickly define instant changes and see the results through interactive simulations. Thus, while flexibility in the production flow reaches its peak, the planning process gains efficiency and accuracy.

Other Products

Learn about all the features of Optiway, which offers end-to-end solutions

and take your efficiency to the next level!

and take your efficiency to the next level!